| tel: 0845 0450336 | |||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||||

| glass worktop and splashback technical details | |||||||||||||||||||||||||

Installation : the installation of the splashbacks/worktops is quite simple and involves applying a 'low modulus' silicone to the base of the glass. You must use 'low modulus' to prevent damaging the splashback. We keep stock of this at £5 per tube. You could also screw the glass to the wall if you wanted but you need to make sure we fabricate the screw holes prior to toughening as you can't drill the glass once toughened. |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

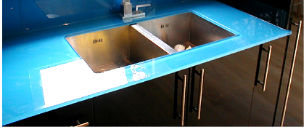

| toughened (safety) details | |||||||||||||||||||||||||

| All of the glass we fabricate is toughened to british safety standard (BS 6206 - EN 12600) regardless of where it's going in the kitchen. We believe that if you intend to use glass as a splashback or a worktop it should be toughened for safety and strength reasons. Also all of our glass has polished edges, once again to keep it safe when handling. One thing you need to be aware of is that once either your glass worktop or glass splashback has been toughened no further fabrication can take place. All of your cut o uts whether they be socket, sink or small notch, need to be cut out at our factory prior to toughening. Unlike other glass products such as laminated glass, you can't cut toughened glass on site. |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| colour application | |||||||||||||||||||||||||

| After the glass has been cut to size, polished and toughened we apply the colour. The colour is created with a very strong specialist resin based spray, which is professionally applied in our spraying booths to the underside of the glass. It is an air drying spray which has been specifically formulated to coat glass. As such we don't need to bake the colour on or worry about the paint degrading years down the line. Due to the nature of the paint we can pretty much create any colour you require but it would take longer and be more expensive. We make sure that we always have the correct pigments and base paints in stock to cover the colours shown on our | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| standard colour chart. | |||||||||||||||||||||||||

| ...glass worktops or splashbacks | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Should you take advantage of our full template and installation service many of the details here shouldn't be of concern. However if you're planning to design and install the glass worktops or glass splashbacks yourself and you have a query which isn't covered here please don't hesitate giving us a call on 0845 0450336 or sending us an email. | |||||||||||||||||||||||||